Hermuler CNC

Products

Hermuler CNC

W43G Series Leveling Machine

Under the condition of large elastic-plstic bending, no mater how different the original bending degree, precision levelling machine uses the “Bauschinger effect” of the material to bend the plate repeatedly, gradually reduce the bending deflection, and gradually change the origina curvature into a single curvature, and finally level it to achieve the leveling accuracy required by the process.

Hermuler CNC

Material Rack Straightening Feeder

This type of machine is mainly used for straightening materials with a thickness of 0.3~3.2mm, and 11 sticks are generally used. At present, the maximum width of the corresponding materials is 800 mm. The whole line occupies a small area, and this series of machines with a thickness of more than 500mm will add material supporting arms and inlet pressing devices for auxiliary feeding.

Hermuler CNC

GZ Series CNC Bandsaw Machines

GZ Series CNC Bandsaw Machines is ideal for cutting solids, tubes and profiles of a variety of materials including, but not limited to, iron, steel, Aluminum alloy, and bearing steel. It is widely used for mass production industries, especially for the bulk sawing of automotive parts, bearings, and gears.

Hermuler CNC

GB Series Bandsaw Machines

GB Series Bandsaw Machines is semi-automatic operation, easy to understand and use control panel.It is ideal for cutting metal solids, tubes and profiles with a variety of materials including, but not limited to, iron, steel, aluminum alloy, stainless steel and bearing steel.

Hermuler CNC

GZX Series CNC Pivot Bandsaw Machines

GZX Series CNC Pivot Bandsaw Machines is ideal for angle cutting of profiles and 90 degree cutting of solids, tubes and profiles of a variety of materials including, but not limited to, iron, steel, Aluminum alloy, and bearing steel. The saws are widely used for mass production industries.

Hermuler CNC

GBX Series Pivot Bandsaw Machines

GBX Series Pivot Bandsaw Machine is equipped with a 60-degree swivel head mitering capability which makes it ideally suited for jobs with many angle cuts and limited workshop space. It is specially designed for the angle cut of tubes and profiles, and also suitable for the cut of 90 degree solids, tubes and profiles with a variety of materials including, but not limited to, iron, steel, aluminum alloy, stainless steel and bearing steel.

Hermuler CNC

XG Series High Speed Circular Saw Machines

XG Series High Speed Circular Saw Machine

adopts a high-strength integrated casting body equipped with imported high-precision guide rails and ball screws, which ensures the stability of overall equipment performance and meets the high-level requirements of processing objects for precision.

Hermuler CNC

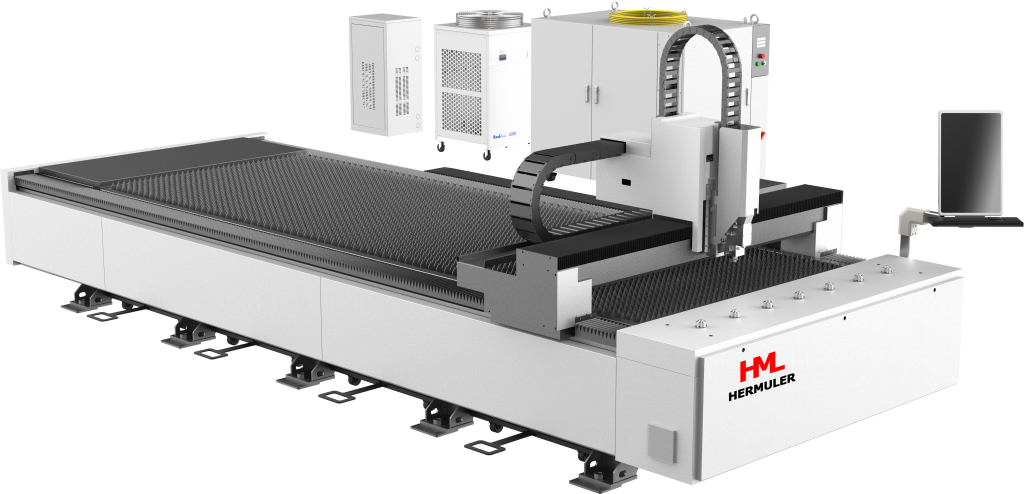

Dual drive fiber laser catting machine

Dual drive fiber laser catting machine been worked to help you cut several metal sheet, such as stainless steel, aluminum alloy sheet, carbon steel sheet copper etc.and it has the exchange platform for you choose to automatic feed the sheet to improve work efficiency.

Hermuler CNC

Dual drive fiber laser catting machine

Dual drive fiber laser catting machine been worked to help you cut several metal sheet, such as stainless steel, aluminum alloy sheet, carbon steel sheet copper etc.and it has the exchange platform for you choose to automatic feed the sheet to improve work efficiency. Single table, double auto feeding table, with or without protective cover optional

Hermuler CNC

Fiber laser pipe cutting machine

Fiber laser pipe cutting machine is professional tube cutting software and matching nesting software are implemented to draw graphics or text at random or instant processing, giving handy processing, simple and easy using experience.

Hermuler CNC

Handheld laser welding machine

Handheld laser welding machine been worked to help you weld several metal sheet, such as stainless steel, aluminum alloy sheet, carbon steel sheet etc.and it has the cleaning&cutting optional function for you choose.

Hermuler CNC

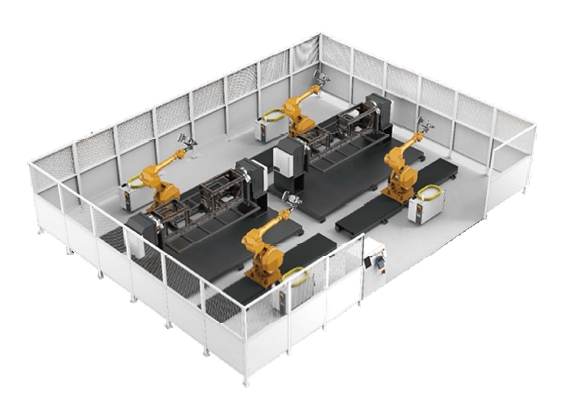

Robot automatic welding

As a new model of welding robot, in the aspect of manufacturing technology, die-casting technology is adopted, the density of the robot is increased, the thickness is narrowed, and the flexibility is enhanced. In terms of appearance, it adopts simple straight back design. In terms of structure, the gold ratio is used to design the length of the small arm and the big arm, which greatly improves the overall rigidity and inertia.

Hermuler CNC

CNC guillotine beam shearing machine

The Guillotine shear machine makes heavy-duty shear affordable. Frame and cutting beam offer maximum rigidity and resistance to deflection and torsional force for accurate shearing of mild steel up to 30mm.

Hermuler CNC

CNC swing beam shearing machine

QC12K NC hydraulic swing beam shearing machine with E21S has an all-steel welded structure and comprehensive treatment (vibration ageing, heat treatment) to remove internal stresses, resulting in excellent rigidity and stability. Precision sliding guides are used to eliminate guide gaps, resulting in high shearing quality. The E21S system is easy to operate.

Hermuler CNC

CNC electro hydraulic servo press brake

WE67K CNC sheet metal press brake with streamlined design ,high speed ,high precision ,high rigidity. Electro hydraulic servo system,full loop controlling the synchronization of the upper slider. Mechanical compensation on crowning of worktable and deformation compensation on throat, ensuring good bending strength and precision. Backgauge is driven by digital AC servo motor,moved with ball screw,guided by linear guide.

Hermuler CNC

Robot automatic feeding press brake

Robot Press Brake is the result of our goal to develop and improve new bending solutions for the industry. Our robotic press brake and automatic loading/unloading devices work wonders to deliver two levels of automation – process and operation. An extremely reliable solution for unattended production, even at night. Benefit from reduced setup time for tooling, precise bend angles, and superior finished parts. All risks associated with part handling during bending are faced by the robot and not by the operator.

Hermuler CNC

Press arm panel bender

The flexible bending center focuses on solving various complicated sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is resolved from a technical perspective, which effectively improves production efficiency and reduces production costs.Easily realize the arc, press dead edge, back shape, closed shape and other complex sheet metal bending requirements.

Hermuler CNC

CNC hydraulic press brake

WC67K hydraulic press brake machine with E21 has integrated hydraulic control system, which is compact and reduces piping connections, increasing system reliability and ease of maintenance. The machine is synchronised with twisted axes and has two synchronised pendulum arms at both ends of the ram, so that the movement of the ram is always parallel to the working table and has a high resistance to deflection during operation.

Hermuler CNC

CNC Tendem Press Brake

Two WC67Y/K Series in same specification are choosen as main machine with double motor linkage synchro-device, which may work together to process overlong workpiece or operate separately to increase production efficiency. Defection copensation device is fitted, too. Mechanic and fluid servos with mechanic slider are utilized in synchronous device. The stroke of upper slider and the position of rear apron are regulated quickly by machine and micro-regulated by hand with electronic NC display.

Hermuler CNC

Four roll plate rolling machine

The machine adopts the four-roller structure with the upper roller as the main drive. The equipment has the function of pre-bending the end of the plate. The metal sheet can be loaded at one time, and the plate end pre-bending and the roll forming of the workpiece can be completed without turning.

Hermuler CNC

Upper roll unviersal plate rolling machine

The W11S plate bending machine is a comprehensive-functional, easy-to-operate, high-precision equipment that is suitable for bending processing needs of various metal sheets. Whether considering production efficiency, product quality or operational safety, it is an ideal choice.

Hermuler CNC

Edge milling machine

Edge milling machine is mainly used for milling chamfers, straight edges, and U-shaped grooves on steel plates. It can complete the milling work of all four edges, including top and bottom chamfers and fillets, with a single loading operation. The feeding table is equipped with automatic centering, automatic feed, and automatic magnetic adsorption of workpieces, suitable for continuous feeding along the long edge.

Hermuler CNC

Plate crimping press machine

Plate crimping press machine is used to pre bend the iron plate on both sides before pipe making, in order to ensure the roundness of the pipeline and reduce excessive straight edges. The machine adopts CNC control, with low flanging force and a wide range of flange curvature radius.

Hermuler CNC

pipe forming press machine

The advantages of JCOE production process are that it can produce more than 30mm thick steel pipe, which is suitable for the production of extra thick wall steel pipe; the disadvantages are low production efficiency (10 pieces / hour) and large investment. It is usually used for the production of straight seam submerged arc steel pipe with diameter range of 203 – 1422 mm, wall thickness of 8 – 40 mm and length of 10 – 12.5 m.

Hermuler CNC

Tack-welding machine

The pipe is pre-welded by gas protective welder. Then, the pipe is cut off. Pipe is submerged-arc welded off line to internal and external part. After the hydrotester, pipe end facing and beveling machine, welding seam and pipe body detector, the pipe is qualified. The sizing part adopts quick roller change technology to save the roller changing time.

Hermuler CNC

Internal Welding Machine

Pipe is submerged-arc welded off line to internal and external part. After the hydrotester, pipe end facing and beveling machine, welding seam and pipe body detector, the pipe is qualified. The sizing part adopts quick roller change technology to save the roller changing time.

Hermuler CNC

Pipe straightening press

Pipe straightening press machine.Main parts consists of over-length working table of fixed-type, moving frame of gantry type, upper die, movable V-shaped support ,hydraulic system and electrical system.This machine has the function of inching, single and keeping pressure, which can meet the requirement of work-piece straightening.